Changes in demand in the electronics sector in the face of COVID-19

The electronics and household appliances sector can be added to that privileged group of industries that have not been as affected by the global health crisis. On the contrary, they have even seen demand increase for certain product categories despite the overall fall in consumption.

Since the introduction of restrictive isolation measures worldwide, the rise in demand for electronics and household appliance products has been modest but stable, ranging from 8% in the United States to 15% in China.

For example, according to Statista, the sale of electrical appliances in Italy grew by 8.8% between the end of February and the beginning of March of this year in comparison to the same time period in 2019.

Small household appliances: The most popular items during the crisis

The reasons behind this maintenance of consumer interest are easy enough to understand.

During quarantine, most of the indoor activities that people surveyed have reported doing on a daily basis require some kind of gadget or appliance, whether it’s surfing the internet, watching TV, cleaning, listening to music, cooking, talking with family, playing video games, or following the news. Even reading can be considered an electronic activity in the COVID-19 landscape, where it is easier to access ebooks than to order printed books for home delivery.

But this spike in demand for electronics products can also be attributed to the new teleworking routine, which has enabled employees to continue to meet the needs of their job remotely.

This explains the surge in purchases of equipment for teleworking, such as laptops, headphones, webcams, monitors, and printers as well as appliances to replace services that are no longer available, like hair cutting machines for those in need of a trim or washers and vertical irons for consumers who once regularly outsourced their laundry.

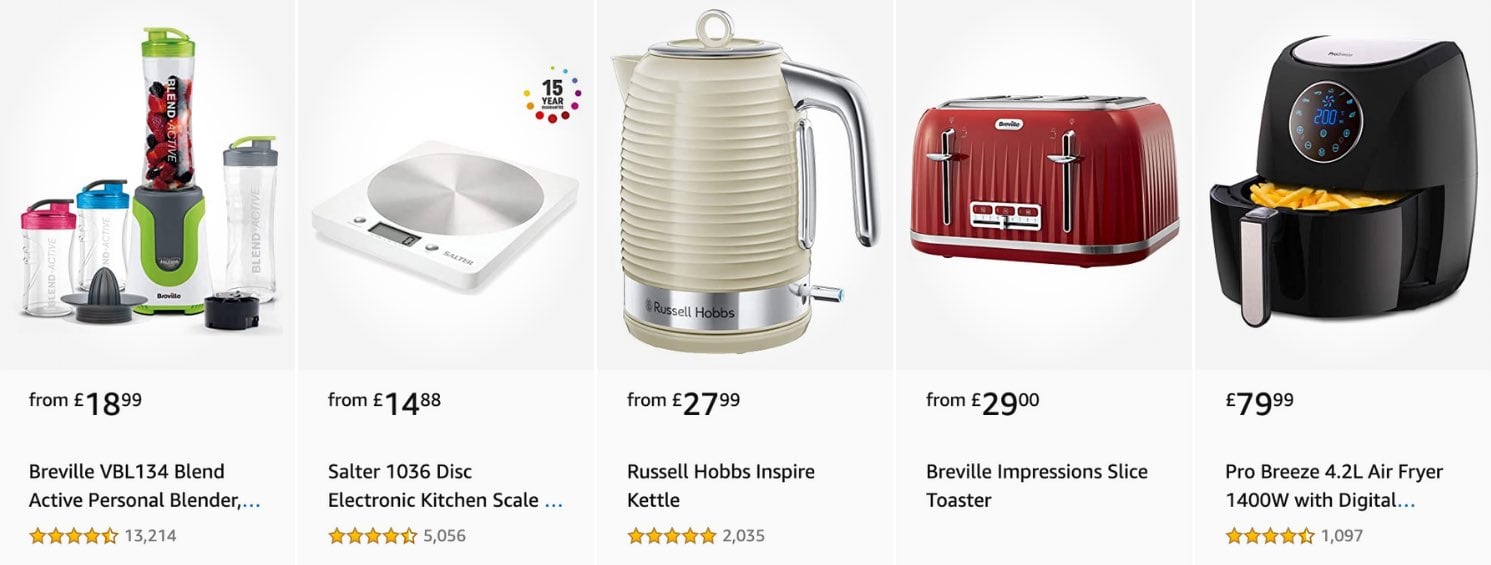

Surprisingly, another sector benefiting from the COVID-19 crisis is that of niche kitchen appliances, which have suddenly risen in popularity as people are cooking more at home. These include sandwich makers, rice cookers, juicers, pasta machines, food processors, kneading machines, bread makers, and mixers.

To get an idea of the acceleration of this specialized demand, one need look no further than China where last February the sale of electric ovens and fryers increased by 280% and 659% respectively.

Other electronics products for which demand has surged during the global crisis

Apart from household appliances, another sector that has seen an increase in demand is memory cards and the export of components for their manufacture (Samsung, the world’s leading producer, has experienced a 20% spike in demand).

Of course, there has also been an uptick in sales of thermometers, an indispensable device both for individual consumers and medical professionals in the midst of the current pandemic. This in turn has led to growing demand for germanium in order to make infrared lenses for hospital thermometers.

Looking to the immediate future, manufacturers and retailers are additionally preparing for a high volume of sales of fans, especially in those hotter regions that will be maintaining quarantine measures during the months of July and August. Meanwhile, other companies are foreseeing a drop in demand for air conditioners that are more expensive and require complex installation.

→ Related: How to sell electronics products in the Newegg marketplace

Problems facing the electronics industry before and after the coronavirus

Despite these encouraging sales figures, the electronics sector still shares the concerns of many other industries today. Here are some of the major uncertainties for electronics manufacturers in the short and medium term:

Disruption of the distribution chain

As is the case in many other industries, most of the world’s electronics and household appliance manufacturers have come to depend on China.

China is home to a number of crucial stages in the product chain, from obtaining raw materials (especially cobalt, lithium, gallium, and indium) to manufacturing, assembling, testing, and distributing products around the world. When Wuhan —a hub for electronics production— became the epicenter of China’s coronavirus crisis, it led to a freeze on exports from the city.

Two-thirds of manufacturers in the United States and Europe have since reported experiencing delays of between three and four weeks in accessing basic components from China and other countries in Asia. Part of the problem here is that many international manufacturers follow a “JIT” (Just-in-Time) delivery model, which means they lacked the production volume that would have anticipated this crisis.

These reductions in the shipment of basic electronics components are affecting every sector imaginable, from DIY gadgets and IT devices to medical and aerospace technology. The biggest story in this regard has been that of Apple limiting its supply of iPhones as a result of the slowdown of production in China. Other companies like LG and Samsung have also closed down factories in Korea, Slovakia, India, and Brazil.

Until now, sales have been maintained thanks to the in-stock availability of products, but shortages of electronics could start to become noticeable beginning in May and continuing into June and July. The good news is that once economic activity resumes in China, the electronics industry can expect to recover faster than other sectors.

In the meantime, the best strategy is not to wait idly for China to return to normal. Many manufacturers may want to consider modifying their production chain in the short and long term as well as seeking out other raw material suppliers and manufacturing sites closer to them. This entails an effort to reorganize the entire distribution chain, something that would consequently decentralize global dependence on Chinese manufacturing.

→ Related: The logistics challenges facing China and the global market

Inventory shortages

For the moment, suppliers and retail companies have enough products in stock to continue meeting demand.

However, due to the disruptions in the production chain we discussed earlier, manufacturers will not be able to keep up with their normal rate of supply, potentially resulting in shortages of inventory and even the temporary cancellation of product lines.

Consumers could also see a rise in retail prices as a consequence of the difficulties facing manufacturers in accessing basic components.

Adoption of digital methods

The cancellation of business events worldwide has affected the electronics industry, whose marketing strategies depend on the presentation of new products and launches on a regular basis. Leading manufacturers have been flexible in adapting these presentations to the digital environment so as not to miss out on promoting brand awareness or communicating with their network of distributors and consumers.

But another aspect to consider here is the current shift toward a teleworking model for which cloud-based software programs are vital. Now more than ever, electronics manufacturers need reliable and secure systems to maintain their operations, foster communication within their teams and among suppliers, distributors, and retailers, and manage their inventories and product catalogs on a global scale.

Product Information Management (PIM) solutions are proving to be an indispensable tool in these times of dramatic digital change. In the post-coronavirus reality, digitization practices will become standard across all industries, making it easier for manufacturers to update their catalogs and adopt new distribution strategies.

Opportunities and courses of action for household appliance manufacturers

The growth in demand we are seeing for certain categories of electronics products should not overshadow the need to prepare for a new digital reality:

- Review available resources and make a realistic forecast of production and distribution rates for the coming months. In addition, prepare necessary courses of action to deal with potential supply cuts and temporary shortages of product inventory.

- Adopt effective product information management strategies that help keep all data related to inventory, shipping, and replenishment projections up to date in real time.

- Provide accurate information to sellers and/or consumers regarding shipping times. Fluid and precise communication between the catalog center (ideally in a PIM) and inventory managers serves to ensure that all teams have the same reference numbers and that all sales channels are up to date.

- Facilitate access to digital catalogs and product content for anyone involved in the distribution chain, from any location or device. Retailers are now having to work faster than ever and manufacturers can help them by providing accurate, easy-to-find content across all channels, including Google Manufacturer.

- Maintain the price of your products. Experts are predicting a possible rise in prices for consumers if manufacturing and inventory levels dramatically decline. Rather than going along with this trend, it is better to avoid giving the impression that your company wants to take advantage of high demand.

- Strengthen customer support, both for the B2B chain as well as for the end consumer. During this period, you may receive more queries and complaints than usual that could affect the quality assurance and performance of your products. Allocating the necessary resources to address these concerns not only helps your customers, but reinforces your brand image in a way that will continue to have a positive impact even after the crisis has passed.

→ Related: The best online marketplaces for selling products in Europe

Conclusion

The challenges of the coronavirus landscape are affecting all industries and despite growth in demand within the electronics sector, this is no time for it to lower its guard.

Electronics and household appliance manufacturers should already be thinking about how to deal with the medium-term problems posed by a China-dependent production chain in addition to preparing for the digital transformation that will be the new normal post-coronavirus.

With intelligent and cloud-based management tools like PIM, you can facilitate remote work, catalog management, and sales promotion across all of your channels. Companies that are quick to embrace these innovative solutions will be better equipped for the marketplace of the future.

.png?width=520&name=Blog%20Partner%20(1).png)