In B2B sales, one-off purchases are rare. Companies order in bulk to meet operational demands, optimize costs, and secure supply continuity. Whether it’s a manufacturer sourcing raw materials or a distributor replenishing inventory, purchasing at scale is the standard.

Bulk pricing is not just about offering discounts—it’s a strategic approach that increases order values, strengthens buyer relationships, and provides predictability in revenue. Here’s how structured bulk pricing creates value for both buyers and suppliers.

Why Bulk Pricing Works in B2B

Professional buyers need to justify their purchasing decisions, often with a focus on cost efficiency and procurement reliability. Bulk pricing aligns with these priorities by:

- Reducing per-unit costs – Buyers improve their margins by ordering in higher quantities, while suppliers move larger volumes in fewer transactions.

- Simplifying decision-making – Transparent volume-based pricing structures eliminate ambiguity and help buyers present clear cost savings to their stakeholders.

- Improving supply chain efficiency – Larger orders reduce the frequency of reordering, minimizing administrative workload and logistics costs for both parties.

- Strengthening supplier-buyer relationships – Businesses that offer bulk pricing create long-term commitments, ensuring repeat purchases and a steady revenue stream.

Now, let’s explore different bulk pricing models and why they matter.

1. Tiered Pricing

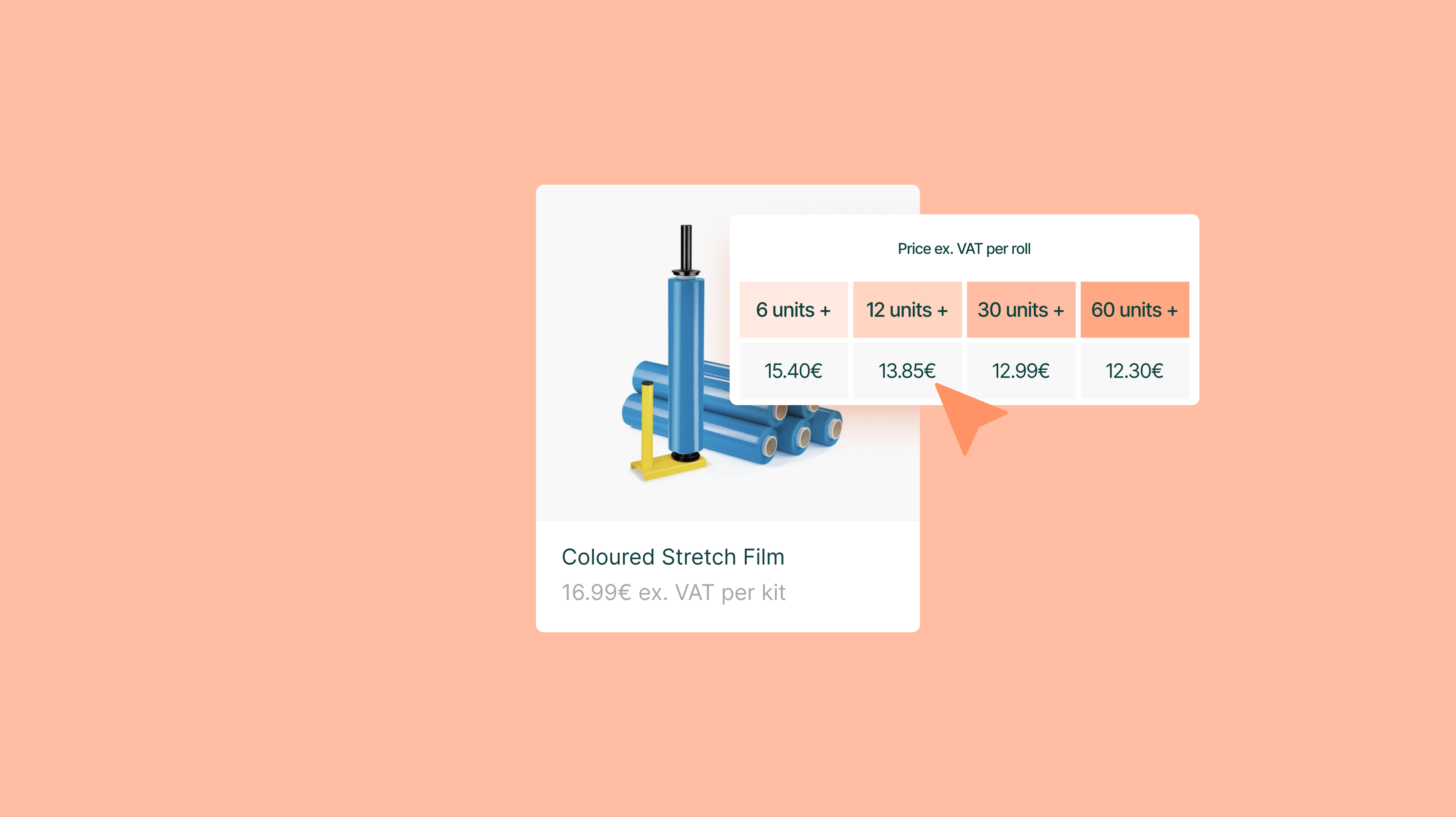

Tiered pricing encourages buyers to increase their order sizes by progressively lowering the per-unit cost at each threshold. This structure appeals to businesses managing production cycles, ensuring they have enough stock while reducing procurement costs.

Suppliers benefit by securing larger commitments upfront, reducing the uncertainty of demand fluctuations. Buyers, on the other hand, get an incentive to purchase beyond immediate needs, optimizing their cost per unit while ensuring supply continuity.

This approach is widely used in manufacturing, where components, raw materials, and consumables are needed in predictable quantities over time.

2. Volume Discounts

Volume discounts apply when a buyer exceeds a specific purchase threshold. Instead of lowering costs per unit in increments, this model offers a percentage reduction on the entire order.

For buyers, this approach is beneficial when making infrequent but large purchases, particularly in industries where storage capacity and working capital are constraints. Suppliers benefit by consolidating demand into fewer, more significant transactions, reducing administrative costs and improving cash flow.

Industries such as wholesale distribution and automotive parts supply often use volume discounts to encourage customers to place fewer but larger orders.

3. Pack or Case Pricing

Pack pricing standardizes bulk purchases by offering predefined quantities, such as cases, pallets, or multi-unit bundles. This simplifies logistics for both the buyer and supplier.

Buyers appreciate this model because it ensures consistency in supply and simplifies inventory planning. For suppliers, it improves warehouse efficiency, reducing the handling time associated with small, irregular orders.

Pack pricing is especially common in industries where products are consumed at a consistent rate, such as food service, healthcare supplies, and industrial materials.

4. Contract Pricing

Contract pricing secures fixed rates over a defined period, usually tied to an ongoing supply agreement. Buyers appreciate price stability, which helps them budget more effectively and avoid price fluctuations.

For suppliers, contract pricing ensures a reliable revenue stream and enables better demand forecasting, leading to more efficient production planning. This model is widely used in industries such as construction, manufacturing, and logistics, where long-term supply chain planning is critical.

5. Subscription-Based Bulk Pricing

Subscription-based bulk pricing applies to recurring purchases where businesses commit to a regular supply schedule. Buyers benefit from predictable costs and uninterrupted stock availability, reducing the risk of shortages.

Suppliers gain a more stable demand pattern, improving inventory forecasting and reducing last-minute production surges. This model is effective for consumables like office supplies, cleaning materials, and industrial lubricants.

6. Bundled Pricing

Bundled pricing groups complementary products together at a lower combined cost, encouraging businesses to purchase a complete solution rather than individual items.

For buyers, this simplifies procurement by ensuring they get all necessary components in one transaction. Suppliers benefit by increasing the total order value while moving related products more efficiently.

This approach is frequently seen in industries like hardware, maintenance, and manufacturing, where multiple products are often needed together.

7. Customer-Specific Pricing

Some suppliers offer personalized bulk pricing for high-value accounts based on order history or long-term potential. Buyers appreciate the exclusivity and cost advantage, while suppliers secure ongoing commitments from key customers.

This strategy is commonly used in sectors where supplier relationships are integral to business success, such as construction materials, industrial components, and wholesale distribution.

8. Freight or Handling Discounts

Shipping costs can be a barrier to bulk purchases, so many suppliers offer freight discounts for large orders. Buyers save on logistics costs, making bulk purchasing even more attractive.

For suppliers, consolidating shipments improves operational efficiency by reducing the frequency of small, costly deliveries. Industries such as restaurant supply, industrial equipment, and construction materials often use this model to encourage larger transactions.

9. Rebate Programs

Rebate programs reward businesses for meeting certain spending thresholds over a set period. Buyers are incentivized to consolidate purchases with a single supplier to maximize their rebate, leading to long-term loyalty.

For suppliers, these programs create a structured approach to driving higher volume sales while maintaining pricing flexibility. Industries such as manufacturing, agriculture, and wholesale distribution often implement rebate programs to encourage repeat purchases.

Final Thoughts

Bulk pricing is more than just a way to lower costs—it’s a strategic tool for driving larger sales, strengthening customer relationships, and ensuring long-term business stability. Whether through structured tiers, volume discounts, or long-term agreements, businesses that implement bulk pricing effectively can create a more predictable and scalable revenue model.

By understanding how different bulk pricing strategies impact both buyers and suppliers, businesses can develop pricing structures that maximize profitability while delivering value to customers. For manufacturers managing complex product catalogs across multiple buyers and regions, a PIM built for manufacturers helps ensure pricing consistency and scalability across all channels.

.png?width=520&name=Blog%20Partner%20(1).png)